How to Design Custom Army PVC Patches for Your Unit or Battalion

Introduction

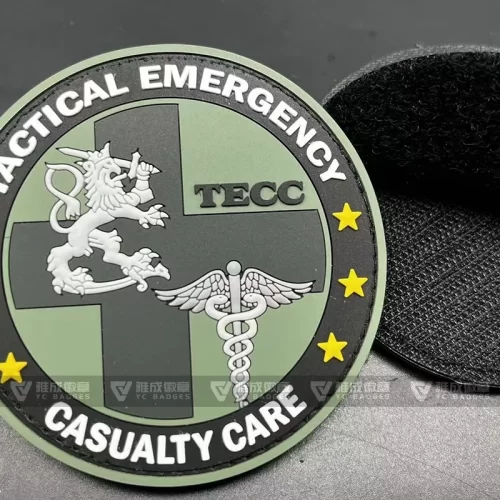

Custom patches play a vital role in military identity, unit recognition, and operational organization.

Among all patch types, custom Army PVC patches have become the preferred choice for modern units and battalions due to their durability, waterproof properties, and professional 3D appearance.

Designing the right PVC patch requires more than just a logo—it involves thoughtful planning around function, visibility, and field conditions. This guide walks you through how to design custom Army PVC patches that meet both tactical and aesthetic requirements.

Why Choose PVC for Army Patches?

Before starting the design process, it’s important to understand why PVC military patches are widely used by army and tactical units.

Key advantages include:

- Waterproof and weather-resistant

- Long-lasting in harsh environments

- Flexible yet tough material

- Clear 3D embossed or debossed designs

- Easy to clean and maintain

These qualities make PVC ideal for combat uniforms, tactical vests, backpacks, and outdoor gear.

Step 1: Define the Purpose of Your Army PVC Patch

The first step in designing a custom patch is identifying its primary function.

Ask the following questions:

- Is the patch for unit identification, rank, or morale?

- Will it be worn on uniforms, vests, or equipment?

- Is visibility or low-profile concealment more important?

Common patch purposes include:

- Unit insignia

- Name and blood type patches

- Mission or deployment identifiers

- Training and commemorative patches

Clear objectives help guide the design direction.

Step 2: Choose the Right Size and Shape

Army PVC patches come in a wide range of sizes and shapes.

Popular shapes include:

- Rectangle and square

- Shield or badge shape

- Circle or oval

- Fully custom die-cut designs

When selecting size, consider:

- Placement on uniform or gear

- Compatibility with Velcro panels

- Legibility of text and symbols

A professional PVC patch manufacturer can recommend optimal dimensions for your use case.

Step 3: Design Your Logo and Artwork

PVC patches allow for precise and detailed designs, but clarity is essential.

Design tips for Army PVC patches:

- Use bold lines and simple shapes

- Avoid overly small text

- Separate color layers clearly

- Optimize artwork for 3D embossing

Raised logos and recessed text are commonly used to enhance readability and depth.

Step 4: Select Tactical or Standard Color Schemes

Color selection is critical in military applications.

Common color options include:

- Full-color unit insignia

- Low-visibility tactical colors

- Desert, woodland, or urban camouflage

- Black, olive drab, tan, or gray

PVC supports accurate Pantone color matching, ensuring consistency across batches.

Step 5: Decide on 3D Effects (Embossed or Debossed)

One of the biggest advantages of PVC patches is their 3D design capability.

Popular effects include:

- Embossed (raised) logos

- Debossed (recessed) text

- Layered depth for complex designs

These effects improve both appearance and tactile recognition.

Step 6: Choose the Right Backing Option

Backing determines how the patch attaches to uniforms or gear.

Common backing options:

- Velcro (hook & loop): removable and mission-flexible

- Sew-on: permanent attachment

- Adhesive: limited or temporary use

For tactical units, Velcro-backed Army PVC patches are the most popular choice.

Step 7: Review Manufacturing and Quality Standards

A reliable custom Army PVC patch factory will guide you through:

- Mold creation and sampling

- Material thickness options

- Color accuracy checks

- Edge trimming and finishing

Always request pre-production samples before mass production.

Step 8: Consider MOQ, Lead Time, and Packaging

When ordering custom Army PVC patches, evaluate:

- Minimum order quantity (MOQ)

- Production lead time

- Bulk packaging or individual poly bags

- Export and shipping options

Factory-direct suppliers often offer better pricing and flexibility for large units or battalions.

Common Design Mistakes to Avoid

- Using overly complex artwork

- Choosing colors with low contrast

- Ignoring Velcro size standards

- Skipping sample approval

Avoiding these mistakes ensures your patches perform well in real-world use.

Why Work with a Professional Army PVC Patch Manufacturer

An experienced manufacturer provides:

- Design optimization support

- OEM and ODM customization

- Consistent quality control

- Competitive factory pricing

- Reliable international shipping

This ensures your custom Army PVC patches meet military-grade expectations.

Conclusion

Designing custom Army PVC patches for your unit or battalion is a strategic process that balances durability, visibility, and identity. By following the steps outlined above, you can create patches that perform reliably in the field while reinforcing unit pride and professionalism.

Partnering with a trusted PVC patch manufacturer ensures your design is executed with precision—resulting in patches built to last in every mission and environment.